There are several plastic fabrication approaches to choose between, and there are broad ranges related to flexibility of shape, startup costs, fees per component, finish time, as well as the scope of production the technique enables. Popular techniques encompass CNC (computer numerical control) machining and vacuum formation, each of which cater to alternative design and style and manufacturing requirements. CNC, for instance, features a medium degree of freedom when considering the shape, a completion time of less than a day, a moderate startup price, steeply-priced individual components, and satisfies large scale manufacturing. Vacuum formation, on the other hand, provides a limited freedom of form, best suited for developing basic forms, and can have a completion period of up to one month. In addition, since there is a vast scale of CNC machines, from simple desktop machines, to significantly more sophisticated pieces of equipment, the startup cost varies from minimal to very high, and the cost per part and the completion time are highly diverse, and reliant on the sophistication of the machine.

CNC Machining

CNC machining is a computer regulated subtractive process, which removes material from plastic as a way to produce the chosen form. The computer is high-tech, with the ability to convert a design into figures by using a computer aided design software program. The figures are able to manipulate the equipment to cut the necessary form. To setup, the pieces of equipment require an intermediate step in the development and validation of tool paths. When the machine is provided with the tool paths, the subtractive process is started. When the construction is finished, the component is cleaned, smoothed, and trimmed.

For low volume plastic component part requests that demand tight tolerances and forms that are tough to mould, machining meets your needs. CNC machining boasts low to medium initial expenses, and can turn out high quality plastic pieces with limited completion times. Yet, with increased product complexity, the charge per element climbs up. Furthermore, this process needs tool access considerations, and certain designs, for instance those with spherical inner channels, are near-impossible to make using CNC manufacturing.

Introduction To Vacuum Formation

Vacuum formation is a method through which plastic is warmed and moulded, ordinarily working with a mould. The size and sophistication of vacuum-forming machines cover anything from low priced desktop equipment to sophisticated production machinery.

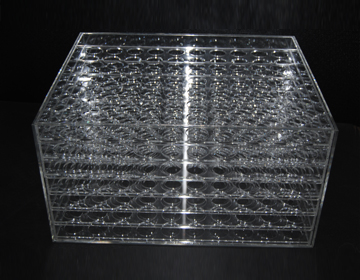

It is usually suited to any venture, from custom-made designs to large-scale manufacturing, considering the large choice of equipment offered and that automation is undoubtedly an option when necessary. Nonetheless, there is little flexibility in the types of design it can create, and is unfortunately exclusively able to create components with basic geometries. Compared to other techniques, tooling prices are low, since vacuum formation only requires low forces and pressures. Normally, for small production sizes the moulds are constructed with 3D printed resin, or even plaster, and for larger development sizes stronger equipment made of metal is used.

The development method begins with a sheet of plastic material getting clamped and warmed up until the plastic becomes mouldable. The plastic will then be put into the mould and cooled down, and quite often fans and other chilling techniques are implemented in order to accelerate the cooling process. The ultimate stage involves any excess plastic being removed. displaydevelopments.co.uk is certainly one site that is loaded with lots of up to date info about bespoke acrylic display boxes. Go here for further details perspex machining.|{Everyone who is looking for much more information with regard to plastic prototyping this online site plastic bend fab has countless more useful resources having to do with plastic prototype companies near me. This blog www.displaydevelopments.co.uk offers quite a bit more info on the subject of small plastic prototypes.

Leave a Reply